Circuitron BD-1 Opto-Electronic Block Occupancy Detector ~ 5501

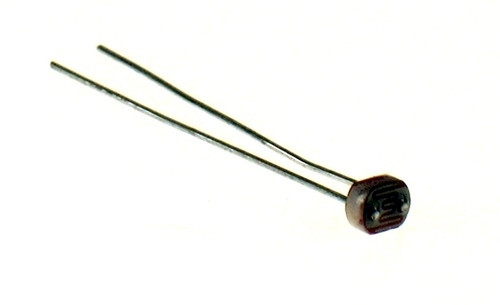

The CIRCUITRON BD-1 is an advanced, integrated circuit design Block Occupancy

Detector operating on a photo-electronic principle that provides positive indication whenever a section of a layout

is occupied by any piece of rolling stock. CIRCUITRON Opto-Sensors are mounted between the ties at the end

points of the block to be protected. Any piece of rolling stock entering the block shades the Opto-Sensors from

ambient room light which then activates the logic circuitry on the BD-1 circuit board. There are no modifications

to the rolling stock necessary. The BD-1 is completely bi-directional and will give proper indications even if a

train leaves a block by reversing direction and backing out. The CIRCUITRON BD-1 also contains all the driver

circuitry necessary to power two-color LED or incandescent lamp block signals at each end of the protected

block. The BD-1 has a 250 ma. output driving capacity. The BD-1HD can handle 500 ma. on each output. For

3 color signaling, additional signal drivers will be necessary. The BD-1 requires a 10-18 volt DC input for proper

operation. The power supply must be filtered. If you do not have a filtered power supply, the CIRCUITRON PS-1

filtered AC to DC Converter is ideal for this application.

INSTRUCTIONS: Please refer to the diagram for labeling and Opto-Sensor locations. The BD-1 can be

connected with .110" solderless connectors or by soldering leads directly to the terminals on the printed circuit

board. If soldering, use a small pencil-type iron and electronics-grade rosin core 60/40 solder (available at Radio

Shack). Use only as much heat as necessary to obtain a good joint and do not wiggle the terminal until the

solder has cooled completely.

1) Mount the circuit board in a convenient location. A section of CIRCUITRON's PCMT makes this a simple

task, or the mounting pads in the corners of the board may be drilled out and the circuit mounted with

screws. If more than one BD-1 is going to be used, they can be mounted in rows for convenient bussing

of the power supply connections between circuit boards. With a 12 volt DC power supply, a maximum of

6 BD-1’s can be bussed together. The reason for this is that there is a a 0.7 volt drop per board.

Exceeding 6 boards connected together may result in insufficient voltage for proper operation of all units.

2) Following the installation instructions packaged with the Opto-Sensors, install two Opto-Sensors at each

end of the block you wish to protect. The actual length of the block does not matter, but it is important

that the room lighting be the same at each end of the block. We recommend that you locate these OptoSensors 2 ties apart in HO Scale. Maintain a 1/2” separation in other scales.

3) Connect one lead from Opto-Sensor SSa to one lead of Opto-Sensor SSb using a light gauge (22-24) wire.

4) Connect one lead from Opto-Sensor SRa to one lead of Opto-Sensor SRb using light gauge wire.

5) Connect the remaining lead of Opto-Sensor SRa to the remaining lead of Opto-Sensor SSa and run a wire

from this connection to the Sensor Drive terminal on the printed circuit board.

6) Run a wire from the remaining lead of Opto-Sensor SSb to the Sensor Set terminal on the printed

circuit board.

7) Run a wire from the remaining lead of Opto-Sensor SRb to the Sensor Reset terminal on the printed

circuit board.

8) Connect a source of filtered DC between 10 and 18 volts to the and Power Supply Terminals.

9) Connect the loads you wish to drive (lamps, LEDs, relays, etc.) between a positive DC source (this may be

the same source that is powering the BD-1 or a separate DC supply) and the and

terminals as shown. If you are using LEDs, you must include resistors as shown. Please note that the

outputs of the BD-1 provide a ground or common connection and that all loads are connected to the

positive supply.

NOTE: If you are utilizing a separate DC power source for your lamps, the negative (-) side of this power source

must be connected to the negative (-) side of the BD-1 power source for proper operation.

DO NOT EXCEED 250 ma LOAD (500 ma for the BD-1HD) ON EITHER OUTPUT UNDER ANY CONDITIONS.

ADJUSTMENTS: All adjustments should be made with the room lighting at the level it will be at during

operating sessions of the layout. Changes of room lighting may necessitate readjustment of the sensitivity controls.

1) Making certain that no piece of rolling stock is shading any of the Opto-Sensors, rotate the Set Sensitivity

Adjuster (PS) until the Set Indicator (LS) comes on. Rotate PS back until LS just turns off.

2) Repeat Step 1 for the Reset Sensitivity Adjuster (PR) and Reset indicator (LR).

3) The BD-1 should now be properly adjusted. Run a train through the block and observe the signals. If they

do not indicate red (occupied) whenever a piece of rolling stock is within the block, repeat steps 1 and 2

above. If you notice any flickering of the indications, you do not have the adjustments quite sensitive

enough. Again, repeat steps 1 and 2 above.

BLOCK OCCUPANCY DETECTOR

BD-1, BD-1HD 211 RocBaar Dr., Romeoville, IL 60446

(815) 886-9010 FAX: (815) 886-9076

Electronics for Model Railroads

Bi-Color LED Target Signals

2 Leaded Bi-Color Light Emitting

Diodes may be connected directly

to the BD-1 outputs as shown.

The current limiting resistors MUST

be included. The value chosen for

the resistors will depend upon the

power supply voltage. In addition,

the GREEN LED die is generally less

efficient than the RED and will

require a lower value resistor to

provide the same light output.

NOTES: The BD-1 has no memory to retain occupancy information when power is removed from the circuit. We have

designed it to always indicate occupied upon first application of power. This will necessitate a “dummy” run through the

blocks to initially set the proper indications when the layout is first turned on. Additionally, if a train attempts to enter an

occupied block, a Green-Red flicker will be noticed upon first entry into the occupied block. This is normal.

If your block has a turnout (siding) within it, it is possible to add an additional pair of Opto-Sensors on the siding wired in

series with the other two pair. With 3 sensors wired in series to each input on the BD-1, however, the sensitivity of the

circuit is reduced to 1/3 of maximum, and it may be quite difficult or impossible to properly adjust the circuit, especially

under uneven lighting conditions. It is possible to use a DT-4 Rolling Stock Detector along with the BD-1 to restore the

sensitivity. Consult CIRCUITRON’s engineering department for additional information.

The CIRCUITRON BD-1 is an advanced, integrated circuit design Block Occupancy

Detector operating on a photo-electronic principle that provides positive indication whenever a section of a layout

is occupied by any piece of rolling stock. CIRCUITRON Opto-Sensors are mounted between the ties at the end

points of the block to be protected. Any piece of rolling stock entering the block shades the Opto-Sensors from

ambient room light which then activates the logic circuitry on the BD-1 circuit board. There are no modifications

to the rolling stock necessary. The BD-1 is completely bi-directional and will give proper indications even if a

train leaves a block by reversing direction and backing out. The CIRCUITRON BD-1 also contains all the driver

circuitry necessary to power two-color LED or incandescent lamp block signals at each end of the protected

block. The BD-1 has a 250 ma. output driving capacity. The BD-1HD can handle 500 ma. on each output. For

3 color signaling, additional signal drivers will be necessary. The BD-1 requires a 10-18 volt DC input for proper

operation. The power supply must be filtered. If you do not have a filtered power supply, the CIRCUITRON PS-1

filtered AC to DC Converter is ideal for this application.

INSTRUCTIONS: Please refer to the diagram for labeling and Opto-Sensor locations. The BD-1 can be

connected with .110" solderless connectors or by soldering leads directly to the terminals on the printed circuit

board. If soldering, use a small pencil-type iron and electronics-grade rosin core 60/40 solder (available at Radio

Shack). Use only as much heat as necessary to obtain a good joint and do not wiggle the terminal until the

solder has cooled completely.

1) Mount the circuit board in a convenient location. A section of CIRCUITRON's PCMT makes this a simple

task, or the mounting pads in the corners of the board may be drilled out and the circuit mounted with

screws. If more than one BD-1 is going to be used, they can be mounted in rows for convenient bussing

of the power supply connections between circuit boards. With a 12 volt DC power supply, a maximum of

6 BD-1’s can be bussed together. The reason for this is that there is a a 0.7 volt drop per board.

Exceeding 6 boards connected together may result in insufficient voltage for proper operation of all units.

2) Following the installation instructions packaged with the Opto-Sensors, install two Opto-Sensors at each

end of the block you wish to protect. The actual length of the block does not matter, but it is important

that the room lighting be the same at each end of the block. We recommend that you locate these OptoSensors 2 ties apart in HO Scale. Maintain a 1/2” separation in other scales.

3) Connect one lead from Opto-Sensor SSa to one lead of Opto-Sensor SSb using a light gauge (22-24) wire.

4) Connect one lead from Opto-Sensor SRa to one lead of Opto-Sensor SRb using light gauge wire.

5) Connect the remaining lead of Opto-Sensor SRa to the remaining lead of Opto-Sensor SSa and run a wire

from this connection to the Sensor Drive terminal on the printed circuit board.

6) Run a wire from the remaining lead of Opto-Sensor SSb to the Sensor Set terminal on the printed

circuit board.

7) Run a wire from the remaining lead of Opto-Sensor SRb to the Sensor Reset terminal on the printed

circuit board.

8) Connect a source of filtered DC between 10 and 18 volts to the and Power Supply Terminals.

9) Connect the loads you wish to drive (lamps, LEDs, relays, etc.) between a positive DC source (this may be

the same source that is powering the BD-1 or a separate DC supply) and the and

terminals as shown. If you are using LEDs, you must include resistors as shown. Please note that the

outputs of the BD-1 provide a ground or common connection and that all loads are connected to the

positive supply.

NOTE: If you are utilizing a separate DC power source for your lamps, the negative (-) side of this power source

must be connected to the negative (-) side of the BD-1 power source for proper operation.

DO NOT EXCEED 250 ma LOAD (500 ma for the BD-1HD) ON EITHER OUTPUT UNDER ANY CONDITIONS.

ADJUSTMENTS: All adjustments should be made with the room lighting at the level it will be at during

operating sessions of the layout. Changes of room lighting may necessitate readjustment of the sensitivity controls.

1) Making certain that no piece of rolling stock is shading any of the Opto-Sensors, rotate the Set Sensitivity

Adjuster (PS) until the Set Indicator (LS) comes on. Rotate PS back until LS just turns off.

2) Repeat Step 1 for the Reset Sensitivity Adjuster (PR) and Reset indicator (LR).

3) The BD-1 should now be properly adjusted. Run a train through the block and observe the signals. If they

do not indicate red (occupied) whenever a piece of rolling stock is within the block, repeat steps 1 and 2

above. If you notice any flickering of the indications, you do not have the adjustments quite sensitive

enough. Again, repeat steps 1 and 2 above.

BLOCK OCCUPANCY DETECTOR

BD-1, BD-1HD 211 RocBaar Dr., Romeoville, IL 60446

(815) 886-9010 FAX: (815) 886-9076

Electronics for Model Railroads

Bi-Color LED Target Signals

2 Leaded Bi-Color Light Emitting

Diodes may be connected directly

to the BD-1 outputs as shown.

The current limiting resistors MUST

be included. The value chosen for

the resistors will depend upon the

power supply voltage. In addition,

the GREEN LED die is generally less

efficient than the RED and will

require a lower value resistor to

provide the same light output.

NOTES: The BD-1 has no memory to retain occupancy information when power is removed from the circuit. We have

designed it to always indicate occupied upon first application of power. This will necessitate a “dummy” run through the

blocks to initially set the proper indications when the layout is first turned on. Additionally, if a train attempts to enter an

occupied block, a Green-Red flicker will be noticed upon first entry into the occupied block. This is normal.

If your block has a turnout (siding) within it, it is possible to add an additional pair of Opto-Sensors on the siding wired in

series with the other two pair. With 3 sensors wired in series to each input on the BD-1, however, the sensitivity of the

circuit is reduced to 1/3 of maximum, and it may be quite difficult or impossible to properly adjust the circuit, especially

under uneven lighting conditions. It is possible to use a DT-4 Rolling Stock Detector along with the BD-1 to restore the

sensitivity. Consult CIRCUITRON’s engineering department for additional information.